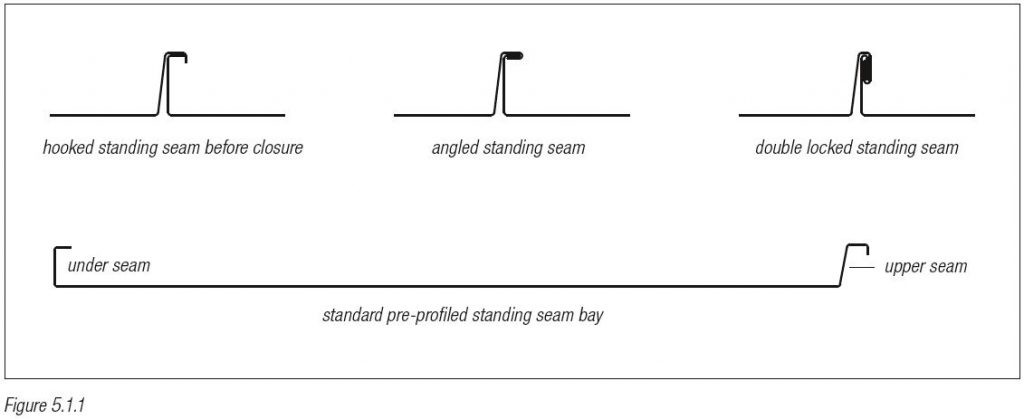

Standing Seam System

The standing seam system makes it possible for a façade to be covered with titanium zinc quickly because preformed bays are used, and the seams are folded mechanically, reducing manual folding to a minimum. The preformed bays are supplied in custom-made sizes and are locked together on site with a single or double fold, by machine or by hand. Aside from straight bays, curved (convex and concave) and tapering bays can be made without problems. The bays are secured to the substructure by means of fixed and sliding clips.

With a standing seam façade, the zinc bays are connected in the longitudinal direction with standing seams (thickness 0.80 mm). The allowable bay width is determined by the wind load and the height of the façade. If the standing bay installed horizontally, then it is recommended to limit the bay width to 300 to 430 mm for optimal work, and to limit the length to about 5 meters for handling reasons. If the standing seam bays are installed vertically, then limiting the bay width to 500 mm or less and the bay length to about 6 meters is recommended for handling reasons. The sheets are connected with a single clip at the top end.